Electrical installations in process automation

Precisely planned and efficiently implemented - for smooth commissioning

The key to success:

Experience, expertise, and a well-coordinated team.

At ESA, all electrical installations are carried out by specialized personnel with years of experience. Precise work, reliability and flexibility are among the basic prerequisites for the rapid implementation and successful commissioning of your system.

Our employees have been working as a well-coordinated team for many years on a wide variety of projects at home and abroad and know exactly what must be taken into consideration in order to ensure efficient operations. Short communication channels and flat hierarchies also ensure uncomplicated project implementation.

Our work in the field of electrical installations begins as early as the building planning stage.

Together with the system manufacturer, we determine the ideal locations for distributors and plan the cable routes. In doing so, we take into account the specific standards and requirements of various industries and countries. In addition to your specifications, the electrical installation is planned and prepared in detail. Examples incklude: Galvanized or stainless steel cable trays, horizontal installation, detectable cable ties, cabling and testing of bus systems, LAN and WLAN infrastructure, and much more.

Norms, standards, tests

High demands on hygiene and quality

In addition to compliance with the country-specific standards such as EN, AS or UL, there are also other challenges in our industries. For those producing high-quality food or compound feed also have high demands in terms of hygiene and quality, especially when working according to the HACCP standard. That is why we also supply distributors that comply with hygienic design to meet FDA and EHEDG standards.

Commissioning

Step by step, everything is brought to life

Once the electrical installation is complete, we start with the I/O check. In conjunction with our system visualization, we check all sensors, units and safety equipment step by step and set them up. During the commissioning of the automated system, all system components are put into operation and tested, the scales are calibrated and the scale logs are prepared. Furthermore, the previously configured ESAweight process control system is tested with the plant control system and the data exchange with the ERP system is put into operation. After the successful start of production, the system is handed over to the customer as part of a joint acceptance procedure.

In the subsequent phase of production support, your employees are trained and we are available to you at any time for optimization.

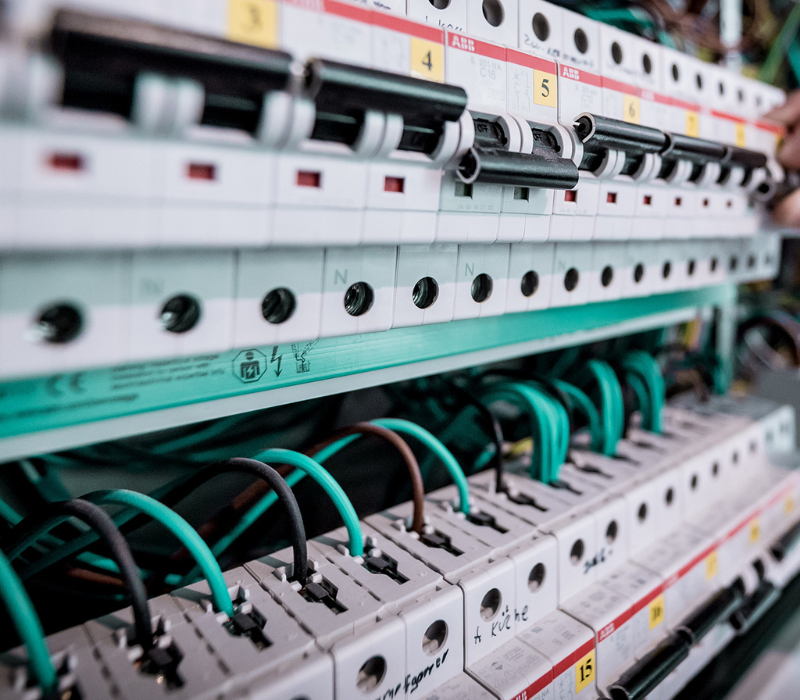

Control cabinet construction

Individually planned and professionally implemented

We also score points for individuality and flexibility in switchboard construction. Depending on the size of the required distributors, these are either built directly in-house or by our long-standing partner close to our company location exactly according to the planning specifications. Thanks to the local proximity and the experience of over 20 years of cooperation, any suggestions for improvement or changes at short notice can be implemented without any problems.

At ESA, you can rest assured that only installation materials and spare parts from reputable manufacturers are used. The majority of these are in stock or can be delivered at very short notice if required. Our employees are trained in specific products and are up to date with the latest guidelines and standards.

We are full-service provider in the field of process automation.

With ESA, you have a reliable partner by your side. We support you from the comprehensive assessment of your requirements through to commissioning. Our ongoing support provides optimization of your production system.

Consulting, Concept and Planning

Detailed needs assessment, a well-thought-out concept, and meticulous planning as a reliable foundation.

Control technology and process visualization

High-quality standards enable a wide range of functions at low costs.

Electrical installations in process automation

Precisely planned and efficiently implemented - for a smooth commissioning.

Process optimization

Optimization of production plants to maintain competitiveness, increase yield and quality.

Retrofit

Modernization of production facilities - increasing efficiency, extending lifespan, and implementing new functions.

Photovoltaics for Businesses

Improve overall economic efficiency with tailor-made solar systems and storage solutions.