Process Automation

in manageable stages

in manageable stages

Become faster, increase quality and still remain flexible. Process automation in manageable, perfectly coordinated stages.

Achieve a substantial increase in your productivity!

ESAweight is our modularly structured process control system, which has been developed precisely to meet the needs of production facilities in the bulk materials industry. ESAweight is configured for the processes of your production facility and your entire flow of goods. It can be extended modularly at any time in line with your growth. Furthermore, we cover many elements of a traditional Manufacturing Execution System (MES), such as production management - also across different locations - or comprehensive recording of operating data. This means that you only need ESAweight as a single system between the plant controller and your ERP system. This reduces the complexity of your systems many times over.

This is why!

Do you want to control your production and flow of goods efficiently and successfully? Then you need transparency and control in all process steps, evaluations as a basis for decision-making, reports, batch logs, OEE (overall equipment efficiency) figures, etc.

Traceability as per EU regulation 178/2002: ESAweight ensures efficient and unbroken tracing of all product flows within the whole automated system.

Legal security, cost savings through avoided recall campaigns and quality assurance are individually calculable benefits you can count on!

Benefit from our growth and our continuously updated products. With a software maintenance contract, we keep your system up to date.

Free-of-charge use of our technical support hotline is also included.

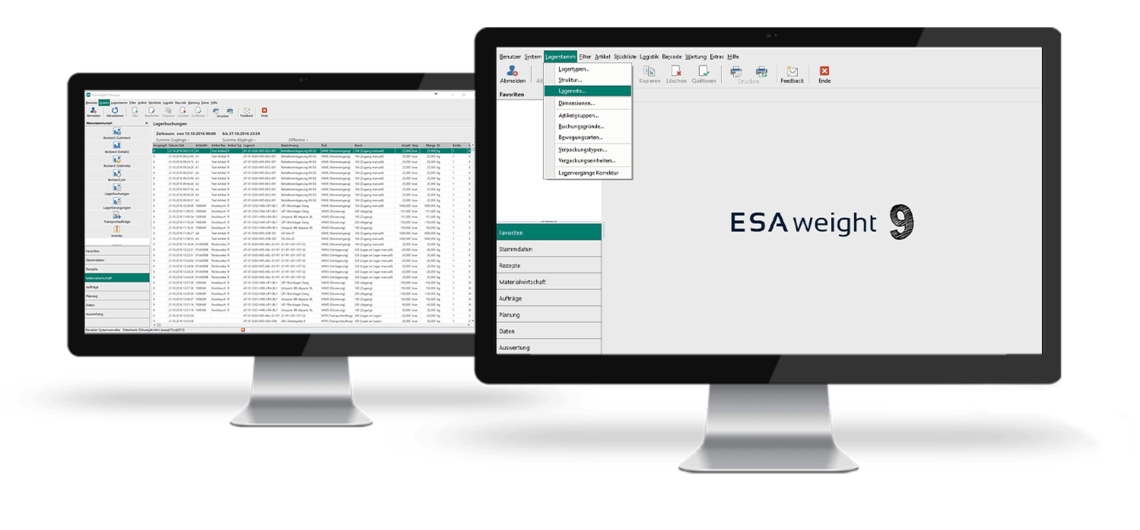

Easy-to-operate user interface, intuitive user guidance, cohesive, modern look & feel, and individual work instructions.

All this guarantees straightforward production control.

Thanks to its modular structure, ESAweight can be extended at any time, growing with your system at a reasonable, predictable cost.

Many different requirements - we supply you with tailor-made, optimised solutions for your company.

Provision of innovative solutions is our highest priority and the main driving force behind our everyday actions. We embrace the responsibility and supply innovative products.

Industry 4.0 with ESA, cutting-edge technology!

THE ADMINISTRATOR OF ALL DATA

ESAweight Manager is used for defining and managing all data as well as for preparing the entire configuration of the ESAweight process control system. All system-specific parameters, such as lines, stations, scales/weighing machines, storage locations, etc., are freely configurable.

Based on an MS SQL database and MS Windows, the data is managed centrally.All the production data is fed back from individual stations to the ESAweight database, from where it can be retrieved, appropriately prepared. By means of the integrated report editor incl. client administration, evaluations and declarations can be created and adapted to meet your needs.

Based on concrete requirements, ESAweight Manager has been continuously updated, thereby providing a selection of comprehensive functions for production, merchandise management, logistics, maintenance and management, including:

ESA covers all production and storage processes from inbound delivery to production through to stock removal.

The following list of modules is supplemented by additional sector-specific production modules.

Acceptance of your delivered raw materials takes place reliably and efficiently. Whether it be loose or bagged goods, with or without sampling - no matter how complex the delivery of your goods may be - ESAtrade meets your requirements.

Traceability thanks to unique transaction numbers, data exchange with the ERP system for purchase orders/deliveries and stocks, weight checking, connection to weighbridges, sampling with data acquisition, label printing for reference samples, fully automatic batch code generation, delivery documents, hazardous goods certificates - An excerpt from the list of inbound delivery tasks - We take care of everything!

ESA Process Control System

PERFECT CONTROL OF YOUR MATERIALS MANAGEMENT

The warehouse management software enables perfect control of your material flows. ESAlogistics supports the management of your raw materials and finished products from goods acceptance to production replenishment, storage and picking through to loading. Special attention is paid here to batch traceability and the shelf life of goods.

Integrated in ESAweight Manager, the material flow manager is the central control element for all transport tasks. It allows logistical goods movements to be controlled and monitored transparently from the point of origin to the destination.

transfer orders are triggered by freely definable strategies and control:

Discover the multitude of possibilities